Chemical Plant

In recent years, petrochemical and basic chemical plants have diversified into higher value-added, larger scale, and overseas locationss. The chemical plants are also required to harmonize with environmental conservation.

We have always responded to the demands of the times, and has successfully delivered a large number of plants, from small-scale projects to national-scale projects. Our projects are not only in Japan but also in Southeast Asia and the Middle East.

We will play a role in business development by flexible and accurate supports to fulfill customer needs with its wealth of experience, technology, and project management accumulated over the past half century.

In Singapore, since 1984, we have developed its engineering capabilities by performing plant construction, enhancement and modification, and routine maintenance services, mainly at PCS and TPC. Today, Singapore Subsidiary has earned a strong reputation and trust as a locally based organization in Singapore.

【Rabigh Phase 1 plan for Petro Rabigh S.A.】

The Rabigh Project is a major project to build one of the world's largest petroleum refining and petrochemical complexes in Saudi Arabia.

Handling Items

■Petrochemical

・Organic chemical production plant

MTBE, budene-1, isobutylene, MMA monomer, acrylic acid, formalin, aniline, nitrobenzene, styrene monomer, methionine, EDC, VCM, phthalic anhydride, BTX, paraxylene, MEK, LSB, maleic anhydride, propylene oxide

・Synthetic resin manufacturing plant

PVC, various types of polyethylene, polypropylene, various types of polystyrene, VAE, EVA, ABS resin, epoxy resin, MMA resin, phenol resin, melamine resin

・Oil and fat product manufacturing plant

Fatty acids, palm oil refining, leather oil

・Rubber manufacturing plant

SBR、EPDM

■Basic Chemistry

・Sulfuric Acid Production Plant

Concentrated sulfuric acid, fuming sulfuric acid

・Inorganic chemical production plant

Hydrochloric acid, nitric acid, porous ammonium nitrate, caustic soda, alumina, PAC, NPK

・Chlorine Recovery Plant

Hydrochloric acid oxidation process

・Other

Various liquid and individual storage facilities, aluminum bus bar fabrication and installation, seismic design and certified piping work in accordance with the High Pressure Gas Control Law

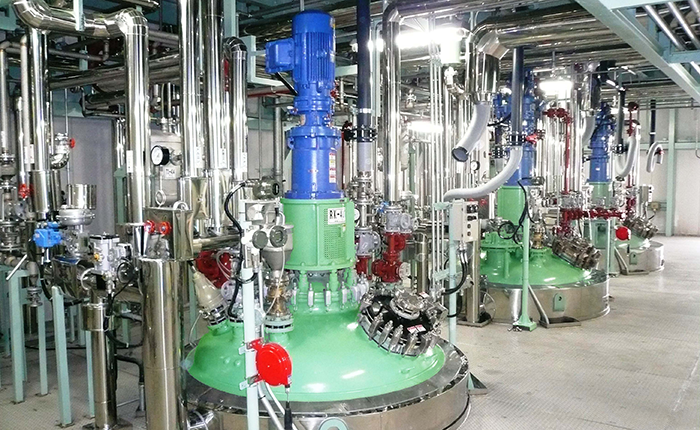

Fine chemical

Fine chemicals are chemical products with high functionality and added value that are produced in high-mix, low-volume quantities and used in a wide range of applications, including pharmaceuticals, agrochemicals, fragrances, and functional resins.

In recent years, the construction of fine chemical plants has been on the rise as the need for fine chemical products increases.

In response to recent market needs, we are working together with customers to construct economical and highly reliable plants, utilizing construction technologies and accumulated know-how cultivated over many years from the user's standpoint.

We also constructs plants that comply with Good Manufacturing Practice (GMP), a standard for pharmaceutical-related manufacturing and quality control.

GMP:Regulations to ensure product quality and safety in the manufacturing process of pharmaceuticals, quasi-drugs, cosmetics, etc.

Handling Items

■Medical Plants

Interferon, active pharmaceutical ingredients, pharmaceutical intermediates

■Agrochemical Plants

Various insecticides and pesticide formulations

■Electronic Materials Plant

Photoresist intermediates, toners, organic EL

■Flavors and Fragrances Plant

■Paint and Ink Related Plants

General paints, powder paints, water-based inks, oil-based inks

■Other Plants

Functional resins, catalysts, adhesives, plasticizers, rubber chemicals, dyes

■Research Facilities

Semiconductor Industry

We started research and development of automatic chemical supply equipment in the late 1970s, when semiconductor manufacturing began to gain momentum, and successfully delivered its first equipment in 1981.

Since then, we have provided many safe and stable systems, mainly this system, contributing to stable operations and labor savings for our customers. Today, we are recognized as global leading supplier of the systems not only in Japan but also in seven countries around the world.

The chemical supply system must be safe, of course, but it is also important to provide a stable supply of chemicals at all times to plants that are expected to operate continuously 24 hours a day, 365 days a year.

We are specialized in chemical supply systems, in which we have gained a great deal of experience in over 1,700 cases and many years of after-sales service.

We accumulated the experience as know-how and constantly fed back to system development and after-sales service to provide highly reliable systems tailored to the characteristics of chemical solutions.

We will continue to respond to increasingly diverse needs and strive to improve customer satisfaction by constructing better systems.

Handling Items

■Automatic chemical supply systems

・Compact supply system (chemical unit) 18-20L container

・Medium supply system 100-200L container

・Large-scale supply system 1㎥ container, tanker truck

■Centralized management system

■Related service business

・Support for customer operations

・Maintenance and inspection work (existing system diagnosis, fluoropolymer lining tank inspection, etc.)

■Specific Technology

・CMP Slurry Supply Facilities

・CCMP slurry dilution and blending facility

・Developer dilution facility

・Fluoric acid dilution facility

・Ammonia dilution facility

・IPA dilution facility

・Mixed acid blending facility

・Constant pressure supply system

・Pure water pressure booster

・High-precision densitometer

Environment

The origin of our environmental technology can be traced back to sulfuric acid and fertilizer manufacturing technology that removed sulfur dioxide from copper smelting flue gas and recovered it as a resource about 100 years ago. We have accumulated experience in plant engineering rigs for the removal of sulfur oxides, nitrogen oxides, and other harmful (polluting) substances that pollute the environment. Today, industrial facilities are required not only to remove hazardous substances but also to reduce emissions of carbon dioxide and other greenhouse gases, and we are committed to environmental considerations in all activities from planning, engineering, and construction.

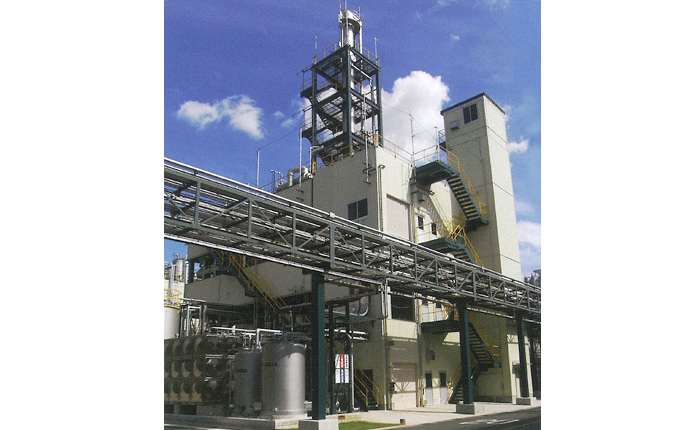

Sulfuric Acid Production Plants

Our sulfuric acid plant originated in Japan's first sulfuric acid production facility in 1888 for the purpose of treating exhaust gas from copper ore roasting. As for us, we provide high quality sulfuric acid plants from various feedstocks based on our extensive experience while accumulating over 30 plants built over the past 50 years. We have built up a large number of construction achievements in the production of sulfuric acid from nonferrous smelting, liquid waste combustion, and waste gas treatment facilities. We are able to offer optimization proposals based on the strength of our proprietary processes and can handle production scales from small to large, and in recent years we have introduced the latest technologies, such as corrosion countermeasures.

Main features of sulfuric acid plants

・The system can be used for plants of various sizes.

We have experience in the plant capacity from 15 t/d to 2,300 t/d and can accommodate various sizes.

・We can handle a wide variety of raw materials.

The raw materials include single sulfur, copper and zinc refining gas, sulfur-containing compound waste liquid, waste sulfuric acid, and dry type desulfurization gas.

・We always provide the best technology.

Based on our own process technology, we can offer a variety of proposals tailored to customer needs.

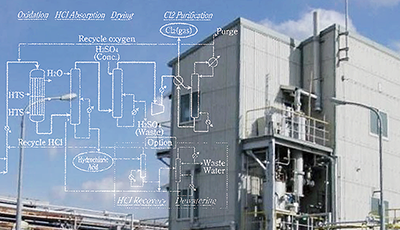

Hydrochloric acid oxidation plants

This technology efficiently converts hydrogen chloride, a byproduct of the chlorine-based manufacturing process, into chlorine using a highly active oxidation catalyst developed by Sumitomo Chemical.

Handling Items

■ Sulfuric Acid Production Plants

Concentrated sulfuric acid, fuming sulfuric acid

■Chlorine Recovery Plants

Hydrochloric acid oxidation process

Comprehensive wastewater from chemical plants, heavy metal wastewater

■Waste treatment related

Waste oil and waste from chemical plants

Owner’s Engineering

With our experience as an owner-engineer company, we have fulfilled many tasks in unison with our clients from the stage of process study. In a wide range of fields from fine chemical batch processes to continuous petrochemical plants, we can assist in the planning and execution of projects from pilot demonstration plants to the creation of FEED packages as a member of your staff. We can provide the best support for your needs, including safer operation and cost reduction to solve your pain point such as shortage of engineers or expertise in your daily operations.

Handling Items

・FS(Feasibility Studies)

・Basic Design

・FEED

・Estimated plant costs

・Equipment Diagnostics

・Deterioration and Damage Analysis

・Repair and renewal from stand-alone equipment

・Process analysis simulation (unbalanced flow, lack of capacity)

・Plant control optimization (PID tuning, etc.)

・CAD data preparation

・Maintenance Documentation

・Technical support for government permits and approvals for overseas expansion

・Overseas procurement (purchasing, quality inspection, delivery management, and transportation)

Main Products: Can manufacturing equipment from China, Korea and Southeast Asia

Project Management

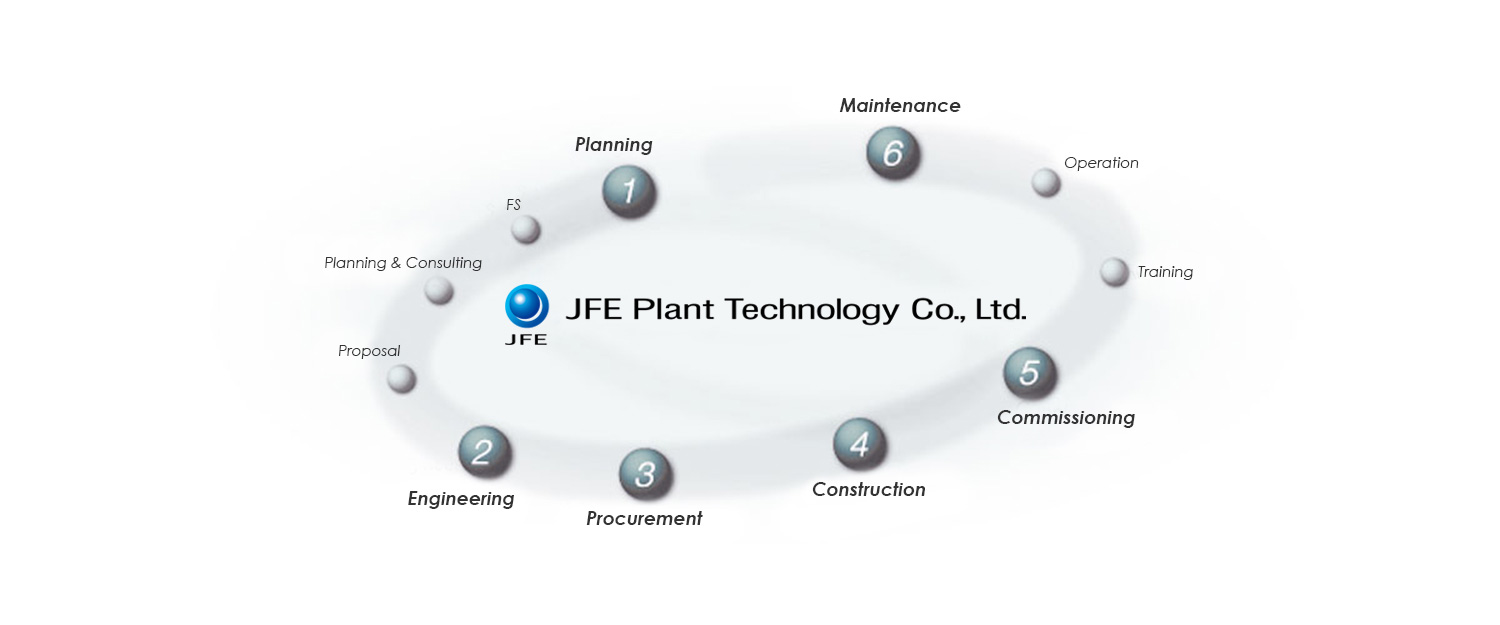

We provides optimal engineering at each stage from feasibility study (FS) to maintenance with its highly reliable project management system, while focusing on the life cycle of a plant over a long period of time. The numerous expertise gained from our extensive experience is a major strength in upstream areas such as FS and design.

In addition, our skilled engineers perform safe and reliable construction work, and together with our global procurement network, we ensure that all aspects of the plant design concept are reflected in the design of equipment. In addition, during maintenance, we are always aware of industry trends and proactively propose improvements, reflecting the valuable knowledge gained from daily operations in new plant designs.

1.Planning FS(Feasibility Studies)/ Planning & Consulting/Quotation Proposal

We cooperate with our clients in planning from the conceptual stage of commercialization. We conduct surveys and studies in accordance with the client's needs, from the commercialization plan to the basic project plan, and provide appropriate advice and various materials.

2. Engineering Basic design, detailed design, design management, and preparation of application documents for government agencies

We determine the basic design, including the overall layout and basic equipment specifications, from the overall perspective of economy, operability, and safety. Then, detailed design of equipment, piping, electrical, instrumentation, civil engineering, and construction is carried out economically and efficiently.

3. Procurement Manufacturer selection & ordering, expediting, quality control, and inspection

We leverage our domestic and global to procure the most suitable products for each project based on a comprehensive review of quality, price, and delivery time. We conduct appropriate quality control and inspections during the manufacturing and transportation processes.

4. Constrution Construction planning and execution, expediting, quality control, and safety control

We have many experienced construction supervisors and professional engineers. Construction work is carried out in a streamlined manner under a consistent system of responsibility through a project management system.

5. Commissioning Manual preparation, commissioning guidance, and S/V (Supervisor) dispatch

Upon completion of construction, We will provide mechanical performance testing and commissioning guidance to verify plant performance. During the commissioning period, Engineers will also be responsible for training your operators and will be available to assist you with the commissioning.

6. Maintenance Modification work, inspections inspections, and equipment diagnostics

We perform modification work, statutory inspections, inspections, and equipment diagnostics according to customer requirements.

Overseas Projects

We supports global companies that are expanding their production bases overseas.

Based in Singapore, Malaysia, we provide optimal engineering services to customers expanding into Southeast Asia while fully leveraging our extensive overseas network.

In addition, we are firmly committed to meeting the various needs of our customers through appropriate collaboration with our Chinese partners.

Procurement

Procurement Policy

We select the best vendor for your project based on a fair, impartial, free competition, and comprehensive evaluation from the view point of quality, delivery, and price.

Through procurement operations that place the highest priority on customer satisfaction, we aim for sound business relationships with our suppliers for mutual development.

Main Procurement Items

We are widely seeking suppliers who are confident in their ability to meet the required specifications, ensure the required quality, and offer competitive prices for the following main items.

We select the best vendor for each project based on a fair evaluation that includes not only price, but also technical capabilities, quality, business management capabilities, and credit.

List of Main Items

・Static equipment (towers, vessels, tanks, heat exchangers)

・Fluoroplastic Lining Equipment for chemical supply facilities

・Related equipment for fine chemicals

・Rotating equipment (pumps, compressors, agitators, etc.)

・Packaged equipment (conveying equipment, filtration equipment, weighing and filling equipment, combustion equipment, drying equipment, service equipment, etc.)

・Electrical equipment (power receiving and distribution equipment, transformer equipment, switchboards, electric motors, electric motor control panels, power supply equipment, etc.)

・Instrumentation (control valves, flow meters, pressure gauges, thermometers, level meters, instrument panels, receiving instruments, etc.)

・Piping components (piping materials, valves, piping accessories, etc.)

・Electrical instrumentation construction materials

Construction

・installation ・plumbing ・Painting ・Heat insulation ・Electrical ・Instrumentation ・Construction ・Construction